The Perfect Balance: How UK Launderettes Can Optimise Heating for Performance and Profit

Step inside any successful UK launderette, and you’ll hear it: the rhythmic hum of washing machines and the gentle roar of dryers. It's the sound of a thriving business. But for the owner, it's also the sound of the gas and electricity meters spinning at a formidable rate. Launderettes are, by their very nature, one of the most energy-intensive businesses on the high street. This presents a unique and critical challenge: how do you balance flawless performance with financial profitability in an era of soaring energy costs?

The challenge is a "dual demand." On one hand, your machinery requires a massive, reliable, and continuous supply of high-temperature hot water to deliver the hygienic, high-quality wash results your customers expect. This is your core operational need. On the other hand, you need to provide a warm, comfortable, and welcoming environment for the customers who wait, ensuring they choose your facility over competitors. This is your customer service need.

Fulfilling both these demands with an outdated or inefficient heating and hot water system is a direct drain on your profits. This in-depth guide is a strategic blueprint for the savvy UK launderette owner. We will dissect the unique energy profile of your business and provide a clear, actionable plan to optimise your systems, slash your overheads, and turn your energy expenditure from a liability into a competitive advantage.

The Anatomy of a Launderette's Energy Bill

To control your costs, you first need to understand them. Unlike a typical retail unit, where energy use is spread across lighting, IT, and modest heating, a launderette's energy profile is heavily skewed. The lion's share of your energy bill is dedicated to just one task: heating water.

- Water Heating (60-70%): This is the undisputed giant of your energy consumption. Commercial washing machines require vast quantities of water heated to specific, high temperatures (often 60°C for a service wash and up to 90°C for boil washes) to effectively remove stains, kill bacteria, and provide a sanitary clean.

- Drying (20-30%): Your tumble dryers, whether gas or electric, are the second-largest consumers.

- Ancillary Use (5-10%): This covers everything else, including ambient space heating, lighting, and powering the machines themselves.

Given that heating water accounts for well over half your total energy usage, it is the single most important area to target for efficiency gains. Even a modest percentage saving here can have a huge impact on your monthly profit margin. The Federation of Small Businesses (FSB) frequently highlights how managing utility costs is critical for the survival and growth of small enterprises, and for launderettes, this means focusing squarely on your commercial laundry heating and hot water generation.

The Heart of Your Operation: Optimising Process Hot Water

The quality of your hot water supply directly impacts the quality of your service. If your system cannot deliver water at a consistent, high temperature, wash quality suffers. If it can't keep up with demand during a busy Saturday afternoon, your customers face delays and your turnover is capped. It's time to diagnose the common issues with traditional systems and embrace a modern solution.

The Problem with Traditional Stored Hot Water

Many older launderettes still rely on a large, insulated storage cylinder (calorifier) linked to a boiler. While seemingly simple, this system is fundamentally unsuited to the demands of a commercial laundry.

- Finite Supply: The system can only deliver as much hot water as is stored in the tank. During a peak rush with multiple machines filling simultaneously, this stored volume can be depleted surprisingly quickly, leaving subsequent machines to fill with lukewarm water.

- Slow Recovery Time: Once emptied, it takes a significant amount of time for the boiler to heat the entire tank back up to temperature, leading to machine downtime and customer frustration.

- Massive Standby Heat Loss: This is the silent profit killer. The system has to burn gas 24/7 just to keep the water in the tank hot, whether you have a single customer or a full house. All night, every night, it's losing heat and you're paying to replace it. This is incredibly wasteful and inefficient.

- Inconsistent Temperatures: Stored water can stratify, with hotter water at the top and cooler water at the bottom, leading to inconsistent fill temperatures and sub-optimal wash results.

The Continuous Flow Revolution: Why Instantaneous Hot Water is King

The definitive solution to all these problems is to abolish the storage tank entirely and move to a continuous flow water heating system. As the name implies, these systems heat water on demand, precisely when it's needed.

When a washing machine's inlet valve opens, a sensor in the heater detects the flow of water. It instantly ignites a powerful, high-efficiency burner and heats the water to a precise, pre-set temperature as it flows through the unit. The moment the valve closes, the heater shuts down, consuming zero energy.

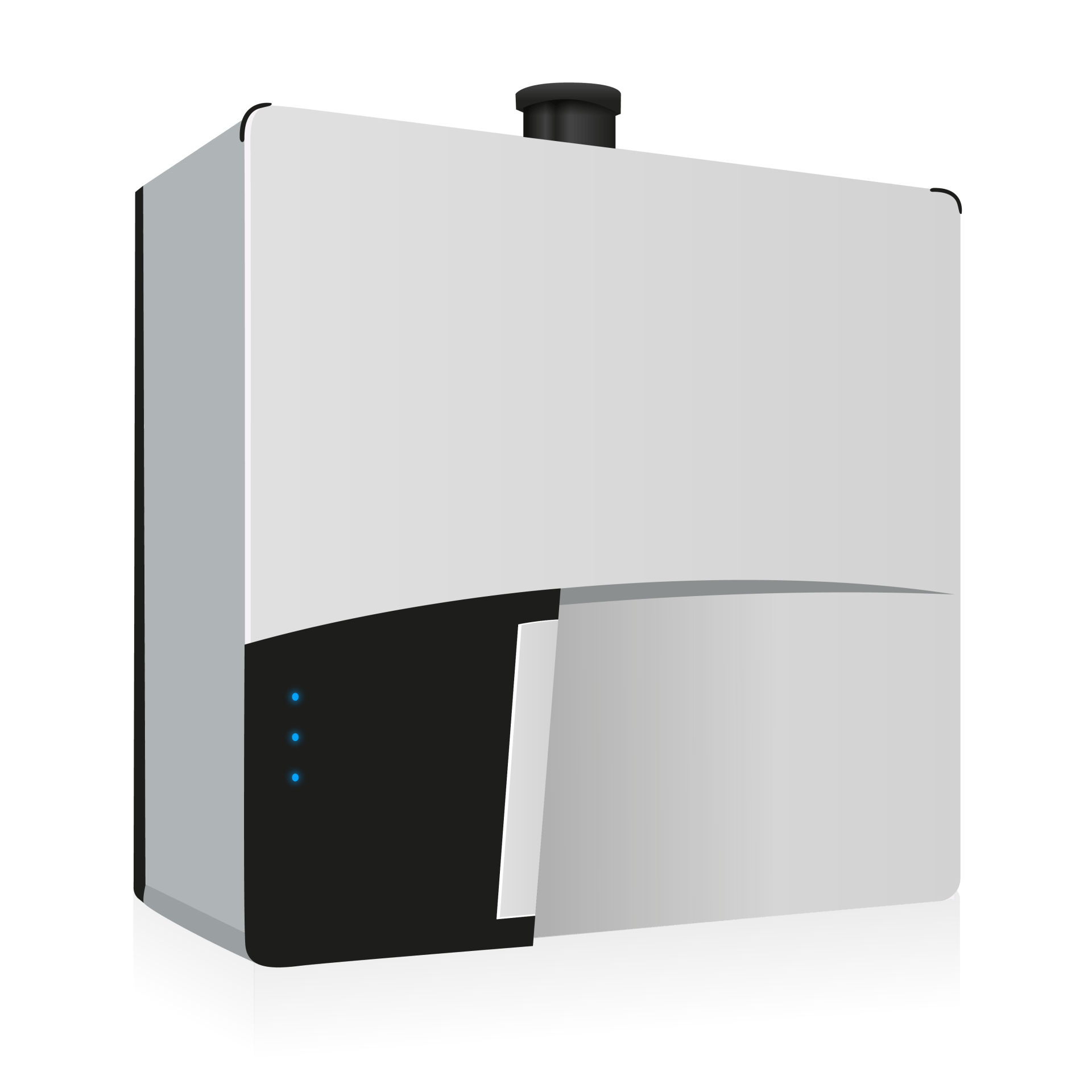

The Ultimate Workhorse: Rinnai Water Heaters

For a demanding commercial environment like a launderette, you need a robust, reliable, and powerful system. This is where Rinnai water heaters excel. They are the global standard for commercial instantaneous hot water and are engineered specifically for the challenges your business faces.

The benefits of installing a Rinnai system for your process water are transformative:

- Endless High-Temperature Water: A Rinnai system physically cannot run out of hot water. It will deliver a continuous, unbroken supply at the exact temperature you need (e.g., 65°C) for as long as your machines are calling for it. This means you can run every machine simultaneously without a drop in performance.

- Commercial-Grade Durability: These are not domestic units. They are built for high-demand applications, with superior components designed for a long and reliable service life, protecting your investment.

- Unbeatable Energy Efficiency: By completely eliminating standby heat loss, a Rinnai system ensures 100% of the energy you pay for is used to heat the water your customers need. This can result in energy savings of 30-50% on your water heating bills compared to an old storage system.

- Compact & Space-Saving: These wall-mounted units are incredibly compact. Replacing a bulky old cylinder can free up valuable floor space in your often-cramped backroom.

Sizing Your System for Maximum Performance

To maximise the benefits, your system must be correctly sized. Our expert engineers will calculate your peak demand based on the number of washing machines you operate and their flow rates. For most launderettes, the ideal solution is a modular system, where multiple Rinnai water heaters are linked together. This provides not only a huge total capacity but also crucial redundancy. If one unit ever needs servicing, the others continue to operate seamlessly, ensuring your business never has to stop.

Creating a Welcoming Environment: Efficient Space Heating

While your machines are the heart of the business, your customers are its lifeblood. A cold, damp, and uninviting waiting area is a major deterrent. Customers will simply take their service wash elsewhere or choose to wait in their car. Creating a comfortable ambient environment is a small but vital part of securing repeat business. However, it must be done efficiently to avoid adding unnecessary costs.

The Customer Comfort Factor

The goal is to maintain a pleasant background temperature without breaking the bank. You don't need to heat the space to tropical levels, but you do need to take the chill off, especially during the colder months from autumn through to spring. This small touch demonstrates a commitment to customer care and dramatically improves the overall service experience. It encourages customers to stay, perhaps using more of your services like the dryers, rather than just dropping off and leaving.

Choosing the Right Boiler: Efficiency is Everything

For your space heating needs, the central component is the boiler. This is entirely separate from your process hot water system and should be chosen with one primary characteristic in mind: efficiency. An older, inefficient boiler can waste as much as £30-£40 of every £100 you spend on gas.

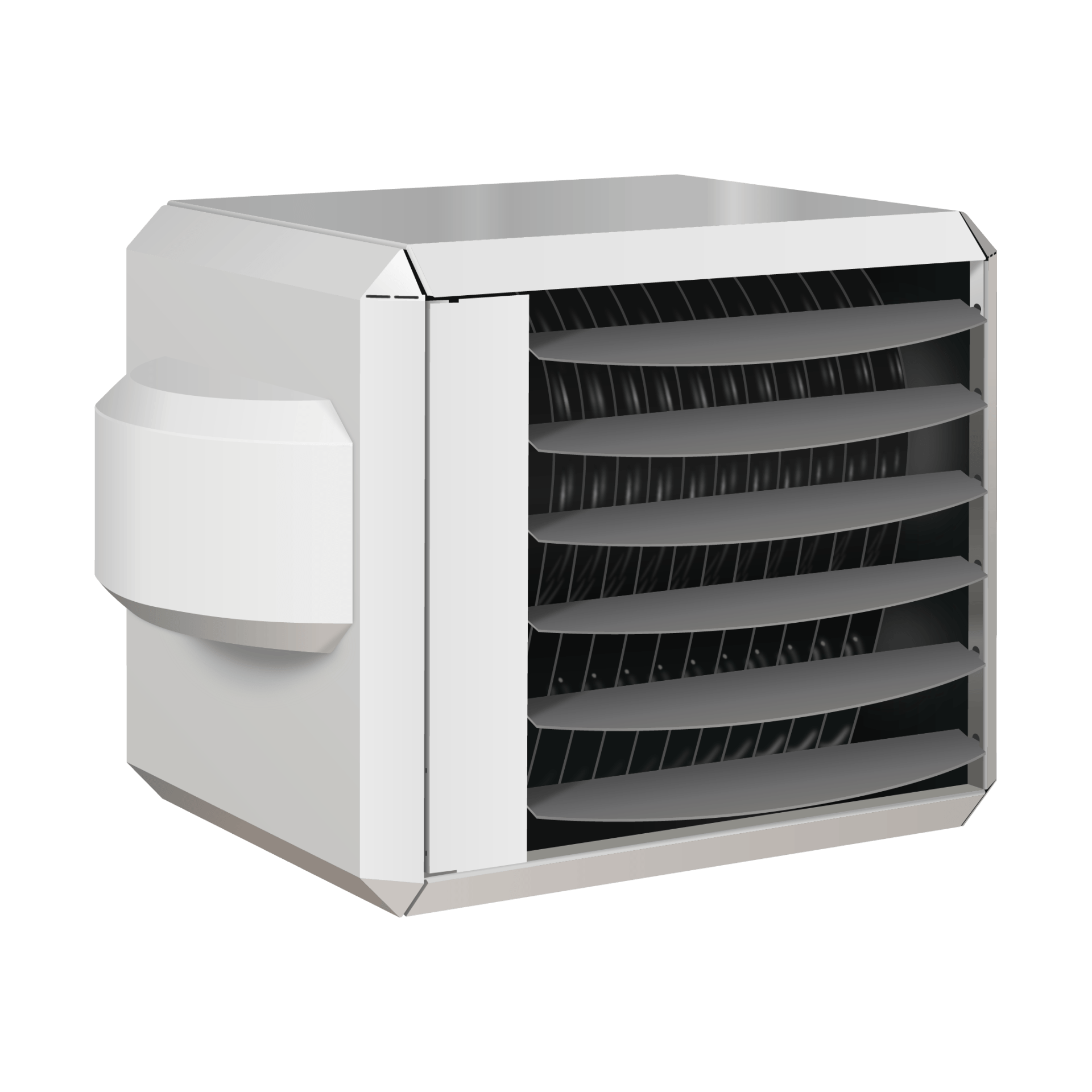

This is why we strongly recommend ATAG boilers. ATAG is a Dutch brand renowned for engineering excellence and producing some of the most energy-efficient boilers in Europe. They are a perfect fit for a cost-conscious business like a launderette.

Key features of ATAG boilers include:

- Market-Leading Efficiency: They consistently achieve exceptional efficiency ratings, meaning more of the fuel you burn is converted into useful heat for your premises, and less is wasted up the flue.

- The iCon Stainless Steel Heat Exchanger: Unlike many boilers that use aluminium, ATAG uses a superior stainless steel heat exchanger. It offers exceptional heat transfer and is highly resistant to corrosion, which is why ATAG can offer a lifetime guarantee on it. This means reliability and a long service life.

- Intelligent Controls: Paired with modern controls, an ATAG boiler can modulate its output to precisely match the heating demand, preventing wasteful on/off cycling and further reducing your gas consumption.

Installing a high-efficiency ATAG boiler to manage your space heating is a smart, long-term investment in reducing your fixed overheads.

Selecting the Right Heat Emitters

The boiler creates the hot water, but you need an effective way to get that heat into the room. For most launderette spaces, a small number of correctly sized, modern radiators fitted with thermostatic radiator valves (TRVs) is the most efficient solution. TRVs allow you to control the temperature in different areas, preventing overheating and saving energy.

Conclusion: From Energy Drain to Competitive Edge

The traditional, compromised approach to launderette heating is no longer viable in the modern market. Running your entire operation from a single, oversized, inefficient boiler is a recipe for high costs and poor performance.

The optimal strategy is a tailored, dual-system approach:

- Process Water: A dedicated, modular system of Rinnai instantaneous water heaters to provide an endless, reliable supply of high-temperature water to your machines, dramatically cutting your primary energy cost.

- Space Heating: A separate, ultra-high-efficiency ATAG boiler to provide comfortable, controllable, and affordable warmth for your customers.

By investing in this modern, balanced approach, you are tackling your biggest operational cost head-on. You are ensuring a superior wash quality for your customers' laundry and a superior comfort level for your customers themselves. The result is a more profitable, more popular, and more successful business.

Stop letting your energy bills dictate your profits. Contact Factory Heaters today for a comprehensive audit of your launderette's heating and hot water systems and discover how much you could save.