Unlock Optimal Comfort: Masterful Heating System Maintenance Tips for Peak Performance

Comprehensive Guide to Diverse Industrial Heaters

Are you prepared to embark on a journey through the diverse world of industrial heaters in the UK?

In the realm of industrial operations, efficiency is essential, and the selection of the right heating solutions can significantly impact your productivity.

From electric heaters to immersion and radiant heaters, the array of industrial heating options available in the UK offers a multitude of possibilities for optimising your operations.

This guide will provide you with a comprehensive understanding of the various types of heaters, including infrared, tubular, and duct heaters, and how they can be harnessed to enhance industrial processes and maximise efficiency.

Understanding Industrial Heating Needs

When considering industrial heating needs, it's crucial to understand the specific requirements of your facility to ensure efficient and effective heating solutions. One efficient method of heating for industrial applications is the industrial electric heater. These heaters are designed to meet the demands of industrial environments, providing reliable and consistent heat for various processes.

When evaluating your heating needs, consider the size of the space, the type of materials being heated, and the temperature requirements. An industrial electric heater can be a versatile and cost-effective option for heating large areas or specific equipment in industrial settings. Understanding the unique demands of your facility will help in selecting the most suitable industrial electric heater for your applications.

Exploring Radiant Heaters

Radiant heaters emit infrared radiation to directly heat objects and people in their path, making them an efficient and targeted heating solution for industrial spaces. Radiant tube heaters, a common type of radiant heater, are often used in industrial settings to provide focused and energy-efficient heating.

Unlike traditional convection heaters that heat the air, infrared heaters offer direct warmth to objects and individuals, resulting in quicker and more effective heating. These heaters use radiant heat transfer to warm up floors, machinery, and people, creating a comfortable environment while reducing energy consumption.

Industrial heaters come in various forms, but radiant heaters stand out for their ability to deliver heat precisely where it's needed, making them ideal for large open spaces or areas with high air change rates. Additionally, radiant heaters are known for their durability and low maintenance requirements, making them a cost-effective heating solution for industrial applications.

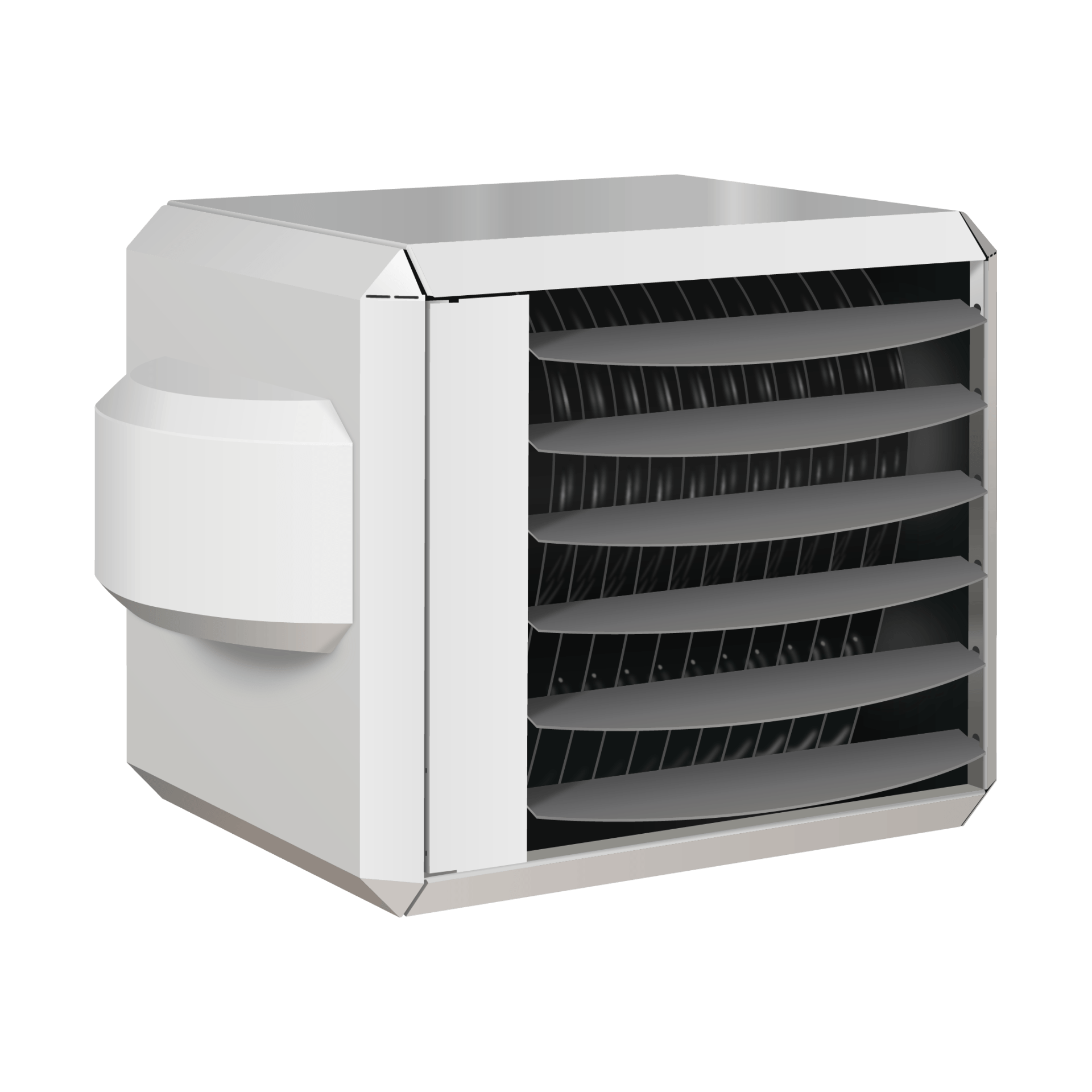

Delving Into Warm Air Units

Exploring the realm of industrial heating, warm air units offer a distinct approach to providing efficient and targeted warmth in large spaces or areas with high air change rates.

These industrial heaters are designed to heat the air and then distribute it evenly throughout the space, ensuring a consistent and comfortable temperature. Warm air units are commonly used in industrial settings such as warehouses, manufacturing facilities, and large commercial spaces where maintaining a warm and comfortable environment is essential for both the well-being of employees and the successful operation of machinery.

By efficiently heating the air and promoting air circulation, warm air units can help to prevent issues such as dampness and condensation, which can be detrimental to both the workforce and the equipment. Additionally, these units are often equipped with advanced controls and thermostats, allowing for precise temperature management and energy efficiency.

Examining Convection Heaters

Convection heaters efficiently distribute warmth throughout industrial spaces, making them an essential component of many heating systems. These industrial heaters operate on the principle of heat transfer through the movement of air. As the heater warms the air, it becomes less dense and rises, creating a convection current that circulates the heated air throughout the space. This process ensures an even distribution of warmth, making convection heaters particularly effective in large industrial areas.

One of the key advantages of convection heaters is their versatility. They can be used to heat liquids, gases, and solids, making them suitable for a wide range of industrial processes. Additionally, convection heaters come in various forms such as duct heaters, air heaters, and circulation heaters, allowing for flexibility in their application.

When choosing convection heaters for industrial use, it's crucial to consider factors such as the required heating capacity, energy efficiency, and the specific heating needs of the industrial processes. By harnessing the power of convection, these heaters play a vital role in maintaining optimal working conditions and enhancing productivity in industrial settings.

Evaluating Infrared Heaters

When evaluating infrared heaters for industrial applications, it's important to consider their efficiency in providing targeted heating for specific processes and spaces. Infrared heaters are a type of industrial heater that use thermal energy to heat objects and surfaces directly, rather than heating the surrounding air.

This targeted heating approach can lead to significant energy savings and increased efficiency in industrial processes. Industrial infrared heaters are known for their ability to heat up quickly and provide instant warmth, making them ideal for applications where rapid heating is required.

The efficiency of infrared heaters is further enhanced by their ability to deliver focused heat, reducing heat loss and ensuring that energy is used effectively. Additionally, the flexibility of infrared heaters allows for customisable heating solutions, making them suitable for a wide range of industrial processes and spaces.

Assessing Electric Heaters

After evaluating the efficiency of infrared heaters for industrial applications, it's important to assess the performance and suitability of electric heaters for achieving targeted heating in specific processes and spaces.

Electric heaters are versatile and can be utilised in various industrial settings, including manufacturing plants, warehouses, and laboratories. When assessing electric heaters, it's crucial to consider factors such as the required temperature range, energy efficiency, and the size of the space to be heated.

Electric heaters come in different types, such as immersion heaters, tubular heaters, radiant heaters, and flexible heaters, each designed for specific industrial heating needs. Assessing electric heaters also involves evaluating their heat transfer capabilities, whether they're used to heat air, liquids, or surfaces.

Additionally, the compatibility of electric heaters with existing industrial heating systems and their ability to integrate with automation and control systems should be considered. By thoroughly assessing electric heaters, industrial facilities can ensure optimal heating solutions that meet their specific requirements while maximising energy efficiency.

Considering Biomass Heating Solutions

Considering the increasing focus on sustainable and renewable energy sources, biomass heating solutions have emerged as a cost-effective and eco-friendly option for industrial heating needs. When considering biomass heating solutions for industrial heaters, it's essential to recognise the potential of biomass as a renewable energy source.

Biomass, derived from organic materials such as wood, agricultural residues, and dedicated energy crops, offers a sustainable alternative to fossil fuels. Industrial heaters powered by biomass can effectively utilise this energy source to generate heat for various processes, contributing to reduced carbon emissions and environmental impact.

Biomass heating solutions can be tailored to meet specific industrial requirements, providing reliable and efficient heat generation for applications such as drying, heating, and power generation. By incorporating biomass heating solutions into industrial operations, businesses can't only reduce their reliance on non-renewable energy sources but also benefit from potential cost savings and a positive environmental footprint.

When evaluating industrial heating options, considering biomass solutions can align with sustainability goals while meeting the demand for effective and environmentally conscious energy sources.

Implementing Efficient Heating Controls

With the increasing focus on sustainable and renewable energy sources, incorporating efficient heating controls becomes pivotal for optimising the utilisation of biomass heating solutions in industrial operations. Efficient heating controls play a crucial role in regulating the temperature and energy consumption of industrial heaters, ensuring that they operate at peak efficiency.

By implementing advanced heating controls, such as programmable thermostats and smart heating systems, industrial facilities can effectively manage their energy usage and minimise wastage. These controls enable precise adjustment of heating levels based on specific operational requirements, leading to significant cost savings and reduced environmental impact.

Additionally, integrating efficient heating controls with the energy source, whether it's biomass, electric, or other renewable options, allows for seamless coordination and maximises the overall heating system's effectiveness. Embracing these technologies not only enhances operational efficiency but also contributes to a more sustainable approach to industrial heating, aligning with the broader environmental objectives.

As industrial heating continues to evolve, the adoption of efficient heating controls will remain instrumental in achieving optimal performance and resource management.

Conclusion

Now that you've explored the diverse range of industrial heaters available in the UK, you're equipped with the knowledge to revolutionise your heating processes.

By understanding the applications and benefits of radiant, warm air, convection, infrared, and electric heaters, as well as biomass heating solutions, you can make informed decisions to enhance the efficiency of your industrial operations.

Implementing efficient heating controls will further optimise your heating systems, unlocking the full potential of industrial heaters.